Pre-Press

Kou Fu operates a state-of-the-art prepress facility making use of the leading technology for designing, impositioning, enhancing, color management, digital proofing and plate making.

Our prepress section is equipped with the latest computer-to-plate (CTP) machine enabling fast and accurate production of printing plates direct from original files, or supplied on a disc. This process ensures finer and sharper images, less production time and an accurate fit on the press.

Kou Fu has a 3D proofing capability that allows virtual viewing of the finished product. A 3D proof can be sent to the customer for approval of the general design and layout. This eliminates the need to ship samples out for customer approval thereby greatly facilitating the fast product development turnaround especially for overseas projects.

Press

Offset Printing

Offers premium print quality at a reasonable price. Equipped with multi-print stations plus an in-line coating station (either conventional water-based coating or UV coating) with automated features reduces set up time and quick changeovers.

Digital Printing

Kou Fu has invested in Digital Printing which provides the flexibility needed to come up fast with new printing concepts. With proven track record for quality, competitive prices and fast turnaround, our digital printing services are excellent for all your short-run or personalized digital printing jobs.

Meet our latest pride, the HP Scitex 15500 which is the largest flatbed digital printer with the maximum size of 65 inches by 126 inches. It utilizes a low-odor printing ink which offers good rub-resistance and surface durability ideal for high-value, indoor applications for merchandising displays.

Post-Press

Publishing

Kou Fu has its own publishing department to handle all types of publishing jobs. We have adequate capacities in cutting, folding, collating, stitching and binding.

- UV Coating

- Aqueous Coating

- Plastic Lamination

- Corrugated Lamination

- Matt Lamination/Varnish

- Spot Lamination

- Foil Stamping

- Embossing

- Debossing

- Texturizing

- Diemaking (woodmould)

Diecut

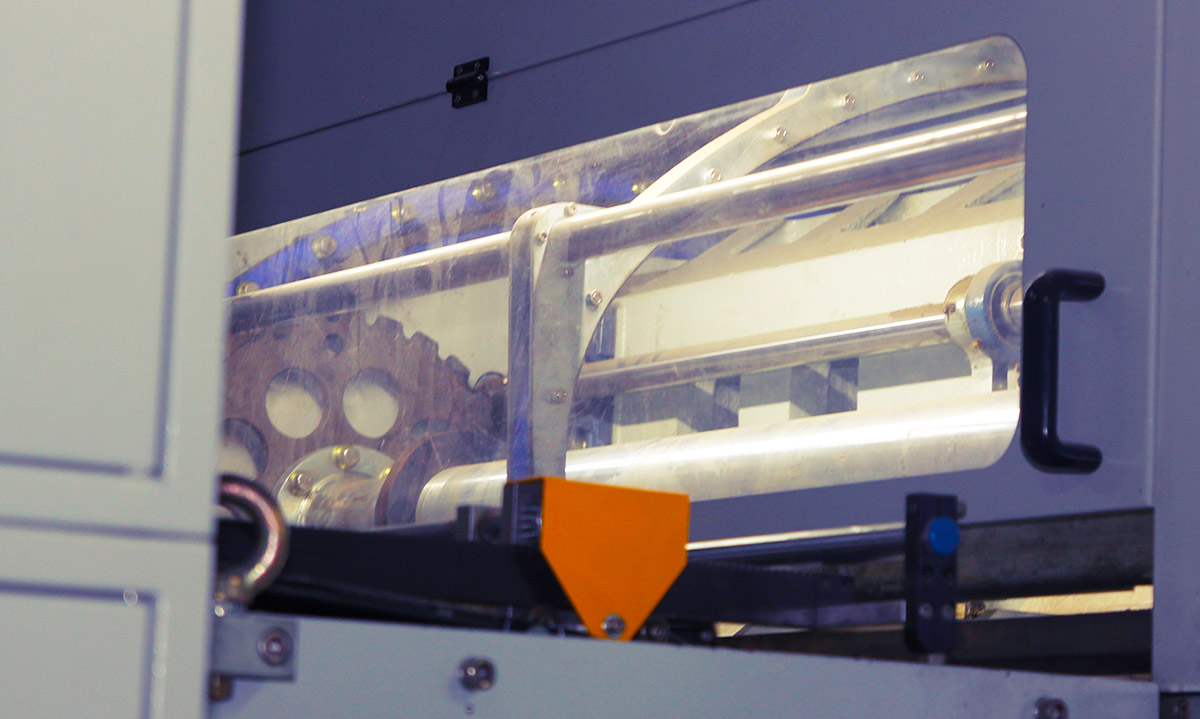

Diecutting is an integral part of our production process. We have a range of auto-diecut as well as manual diecut machines to suit the volume, size and intricacies needed for each item.

Our in-house diemaking section is equipped with laser cutting device for precision cutting with automatic bending and cutting tool, making the blade insertion process easier.

Gluing

Our gluing machines could produce a variety of box styles including the standard folding, double-sided, crash-locked bottom boxes and could process cardboard and corrugated boards.

We recently acquired a 2-joint automatic gluing machine for more efficient and consistent output.